Frigi-Tech Refrigeration Oil Supplement

Anti- Wear Additives

Frigi-Tech contains two anti-wear additives. The first is contact activated and second is friction activated.

CONTACT activated ANTI-WEAR ADDITIVE:

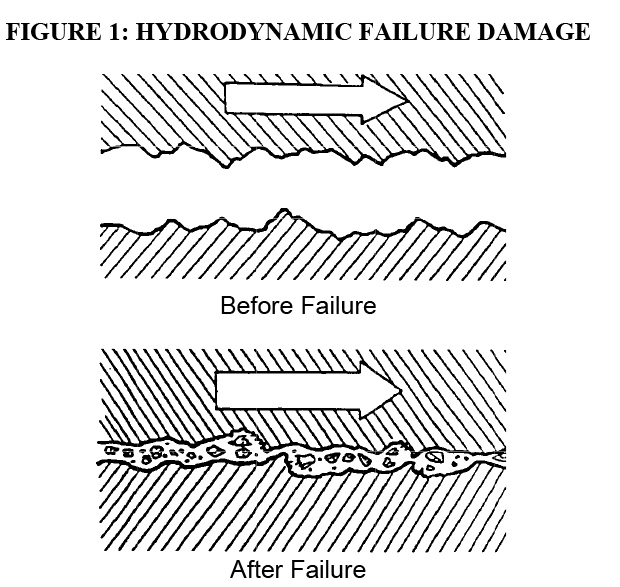

The contact activated additive is the first line of defense. This additive chemically bonds to metal surfaces upon contact and forms a thin extreme pressure barrier. The refrigeration oil, on the other hand, has no strong affinity for metal; and no chemical bonding takes place. Since refrigeration oil is not attracted to metal, it can easily be wiped off or squeezed out under loads. Consequently, it offers little protection when hydrodynamic lubrication fails. Hydrodynamic lubrication failures occur during compressor start-up and shutdown, under extensive loads; or locally on rough bearing damage and accelerated equipment wear. Depending upon the compressor’s design, abrasive metal particles (suspended in the lubrication oil) can migrate throughout the machine and cause further damage.

Figure 1 illustrates the damage that results during hydrodynamic lubrication failure.

The contact activated additive protects against damage incurred during hydrodynamic lubrication failure. This is possible because the additive is chemically bonded to the metal and is not easily removed. The extreme pressure barrier provides a lubrication cushion between two moving

components to reduce metal-to-metal contact and surface wear. This bonding makes the protective barrier difficult to remove. In fact, it can only be removed with a powerful chemical or by mechanical means.

FRICTION activated ANTI-WEAR ADDI IVE:

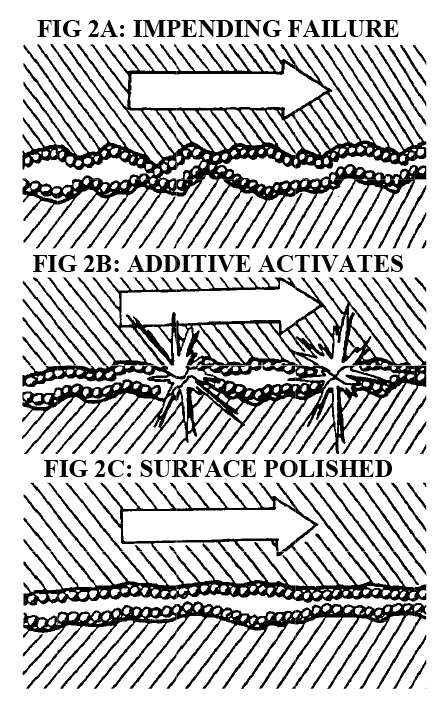

The friction activated additive, the second line of defense against wear, chemically polishes bearing surfaces on an as needed basis. This phenomenon gives equipment treated with the Frigi-Tech Refrigeration Oil Supplement two significant advantages over untreated units. First, the ability to reduce friction by 1500%. Second, the additive provides damage control in the event of total lubrication failure. It is important to note that this chemical polishing takes place only where high friction exists. Figure 2 illustrates how the polishing occurs.

As stated in the previous section, the contact activated additive forms an extreme pressure barrier on metal surfaces. Under heavy loads, this barrier can be worn away. As this happens, the barrier is quickly replaced by the contact additives (which are uniformly distributed in the oil). Under severe operating conditions, such as a rough bearing surfaces or lubrication failures; the protective barrier begins to fail (it wears off faster than it can be replaced). When the moving surfaces come in contact, the friction increases and temperatures rise dramatically at the high wear spot. These high temperatures (over 400˚F) weaken internal chemical bonds of the contact activated additive and allow it to transform into the “friction activated” additive. This additive, in turn chemically interacts with the surface atoms of the metal (to which it is bonded), in such a way as to provide a chemical polishing action. The higher the wear (the higher the temperature), the faster the friction activated additive forms and the quicker the chemical polishing action occurs. When the friction is reduced, the additive is stable and chemical polishing stops. The friction-activated additive performs only when and where it is needed.

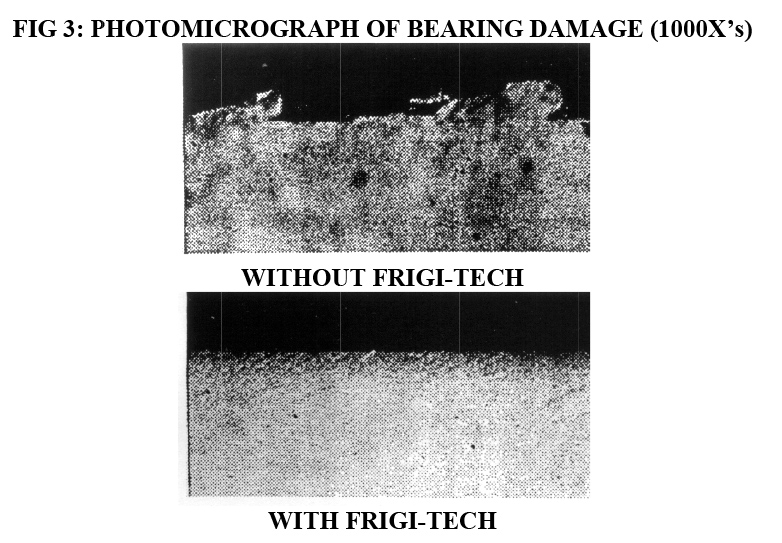

The friction-activated additive can actually eliminate minor bearing defects and rough spots. The result of this action is clearly shown in the two photomicrographs (Figure 3). These photographs compare the cross sections of two roller bearings magnified 1000 times. Both bearings were subjected to the same loads and both received the same amount of bearing wear. After the bearing on the right was damaged, a small quantity of Frigi-Tech was added to the machine. When this same bearing was subjected to additional heavy loads (high friction) the friction activated additive was triggered, and the bearing surface was polished to a mirror finish.

For a compressor that is already in service, the additive will polish rough bearing surfaces, thus allowing it to operate smoothly. For the new units, the additive will accelerate the break-in period and provide superior protection against bearing damage. The resulting reduction in compressor friction reduces wear, vibration, and noise. It also lowers energy consumption and extends compressor life.

This process of reducing compressor friction and energy consumption may take 3-5 days. The length of time, as well as the percent reduction in energy consumption depends on the condition of the unit treated. A larger change will occur sooner in a machine that has high friction, than in an identical machine that is in better mechanical condition.

The friction-activated additive can actually eliminate minor bearing defects and rough spots. The result of this action is clearly shown in the two photomicrographs (Figure 3). These photographs compare the cross sections of two roller bearings magnified 1000 times. Both bearings were subjected to the same loads and both received the same amount of bearing wear. After the bearing on the right was damaged, a small quantity of Frigi-Tech was added to the machine. When this same bearing was subjected to additional heavy loads (high friction) the friction activated additive was triggered, and the bearing surface was polished to a mirror finish.

For a compressor that is already in service, the additive will polish rough bearing surfaces, thus allowing it to operate smoothly. For the new units, the additive will accelerate the break-in period and provide superior protection against bearing damage. The resulting reduction in compressor friction reduces wear, vibration, and noise. It also lowers energy consumption and extends compressor life.

This process of reducing compressor friction and energy consumption may take 3-5 days. The length of time, as well as the percent reduction in energy consumption depends on the condition of the unit treated. A larger change will occur sooner in a machine that has high friction, than in an identical machine that is in better mechanical condition.

The friction-activated additive can also provide damage control in the unfortunate event of total lubrication failure. Total lubrication failure can easily wreck a compressor to the point that it is not repairable. However, because the additive’s chemical polishing significantly reduces bearing wear and damage; it could make the difference between a minor repair and a complete unit replacement. This not only saves repair cost, but also minimizes unit down time.

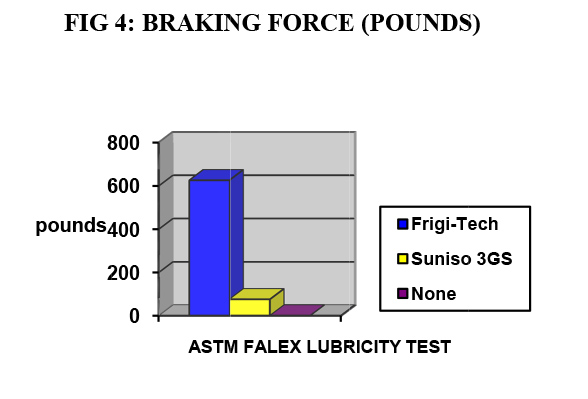

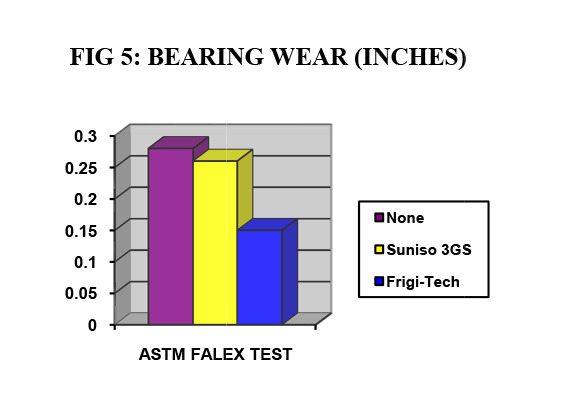

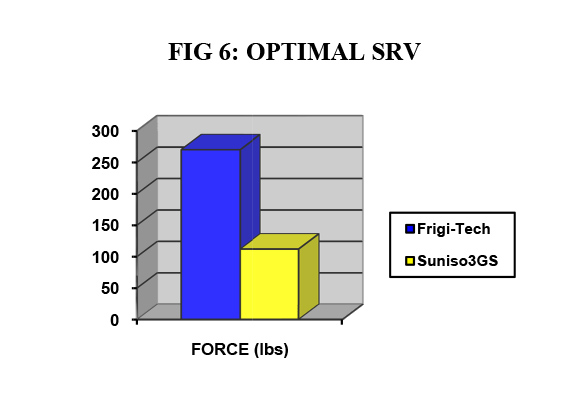

Frigi-Tech’s high performance anti-wear technology can be demonstrated through several standard tests, which can be performed in a well-equipped testing laboratory. Results from two such tests, the ASTM Falex and the Optimal SRV test are presented in Figures 4,5, and 6.

The ASTM Falex Test utilizes an unhardened roller bearing as a brake against a motor driven spinning disk (Figure 4). The force required to stop the disk is a measure of the coefficient of friction, and the amount of bearing damage is a measure of the anti-wear characteristics. The test results showed that when 5% Frigi-Tech Refrigeration Oil Supplement was added to the refrigeration oil, the amount of force required to stop the disk increased dramatically.

The test results clearly show that compressor friction and wear can be reduced with a Frigi-Tech treatment (Figure 5).

Despite the fact that this higher braking force was exerted 10 times longer than the dry test, or the pure oil test, the amou t of bearing wear damage was significantly less when Frigi-Tech was added.

The Optimal SRV test (Figure 6) is a more scientific measure of the coefficient of friction. This sensitive test involves sliding a weighted metal object across the surface of a lubricated metal plate. The weight of the metal object is then increased incrementally. The test revealed that the coefficient of friction dropped more than 50% when the oil was treated with Frigi-Tech. Ordinary refrigeration oil failed at 112 pounds, where as the same oil with 5% Frigi-Tech added did not fail until the weight exceeded 270 pounds. This again illustrates how adding Frigi-Tech can enhance the lubrication qualities of refrigeration oil.

OXIDATION INHIBITOR

Frigi-Tech Refrigeration Oil Supplement also contains an oxidation inhibitor to preserve the oil. All lubrication oils oxidize or deteriorate over time. As oils degenerate, corrosive organic acids and sludge are formed; which can damage the precision compressor components, and interfere with the proper distribution of the lubricant. Frigi-Tech’s oxidation inhibitor chemically interacts with and disrupts the oil oxidation process thus allowing the refrigeration oil to perform at peak levels longer. The resulting extended refrigeration oil life translates to less frequent oil changes and longer equipment life.

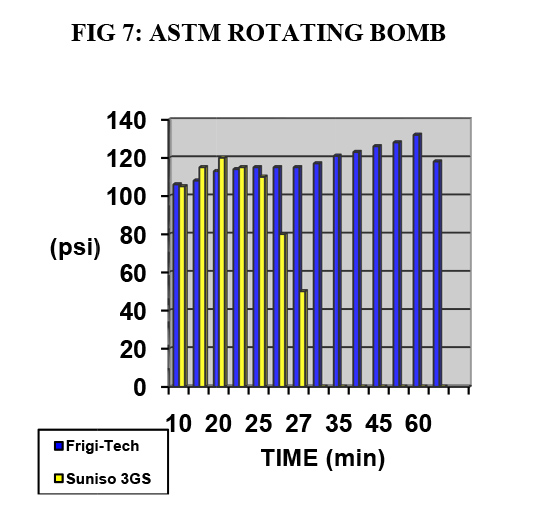

The effectiveness of Frigi-Tech’s oxidation inhibitor can be quantified in an ASTM Rotating Bomb Oxidation Test (Figure 7). This standard test involves putting oil in a small metal bottle (bomb) and then pressurizing it with oxygen up to 90 psi. The container is then heated to 302˚F (150˚C) and the pressure is monitored. The pressure rises initially (due to thermal expansion) and then declines.

Bomb pressure declines because oxygen is consumed when oil oxidizes. The length of time that the bomb pressure is above 100 psi is a measure of the oil’s stability and resistance to oxidation. The ASTM Rotating Bomb Oxidation Test results reveal that oil treated with Frigi-Tech maintains its oxidation resistance 3 times longer than untreated refrigeration oil does. These laboratory results indicate that refrigeration oil life is extended when Frigi-Tech’s supplement is added.

CORROSION INHIBITORS

Frigi-Tech Refrigeration Oil Supplement has corrosion inhibitors to protect precision compressor components. It is not uncommon to have corrosive acids in refrigeration systems. Acids can be generated by water contamination, or by the oil oxidation process itself. As mentioned previously, Frigi-Tech’s contact activated anti-wear additive forms a protective barrier on all metal surfaces. This barrier resists acid and protects the metal from corrosion damage because the additive-to-metal bonds are not easily broken.

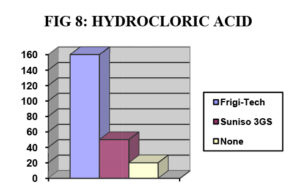

The corrosion resistance can be illustrated by timing how long this barrier survives while submerged in laboratory grade hydrochloric acid (Figure 8). Because aluminum corrodes rapidly in HCI, aluminum foil as used as the carrier (or coupon) for testing the corrosion resistance of ordinary refrigeration oil, and the same oil with 5% Frigi-Tech added. The length of time it takes to corrode the aluminum coupon is a measure of the oil’s corrosion resistance. It was found that the coupon treated with Frigi-Tech resisted the hydrochloric acid almost three times longer than the coupon coated with straight refrigeration oil.

This laboratory test explains how Frigi-Tech Refrigeration Oil Supplement protects equipment life.

SURFACTANT AGENTS

Frigi-Tech Refrigeration Oil Supplement uses surfactant agents to reduce foaming, and to minimize residual oil film thickness. It is desirable to reduce foaming in compressors because the gas trapped in foam bubbles is a poor lubricant. Minimizing oil foam in the compressor is important to insure proper lubrication.

Foaming also causes problems in evaporator coils. After the liquid refrigerant and refrigeration oil mixture pass through the expansion valve, the refrigerant absorbs heat and vaporizes. Because the refrigerant and the oil are miscible and well mixed, when the refrigerant vaporizes; it does so in small pockets or bubbles. Consequently, a significant amount of foaming occurs as the refrigerant vaporizes while passing through the evaporator. This foaming action can be seen by taking a refrigeration oil sample that is laden with refrigerant.

Reducing foam in the evaporator coil is important because foam slows the heat transfer process. A good analogy would be comparing oil foam to a Styrofoam coffee cup. In one case, the foam is trapped in a liquid, and in another case; it is a trapped gas in a solid. As you know, it takes surprisingly little Styrofoam to keep the heat of scalding coffee from your hands. Because the oil foam acts as an insulator, the amount of heat transfer (cooling) in the evaporator is restricted. Therefore, reducing oil foaming in the evaporator coil increases the coil’s heat transfer efficiency, which, in turn, increases the refrigeration or air conditioner unit’s cooling capacity. Frigi-Tech’s anti-foam additive reduces foaming and increases the cooling capacity. Controlled laboratory test found that the temperatures of the airflow exiting the evaporator coil dropped 2˚F after Frigi-Tech Refrigeration Oil Supplement was added. This increase cooling efficiency results in energy savings because the compressor operates fewer hours, for the same amount of cooling. The overall maintenance cost is also reduced because the unit is subjected to less wear and tear.

The surfactant agent that reduces oil foam also reduces refrigeration oil film thickness that accumulates inside condenser and evaporator coils. Because this oil film acts as an insulator in both coils, heat transfer is impaired. While a reduction in oil film build-up has been verified, it is difficult to precisely quantify the reduction since direct measurement is impractical. It has been Frigi-Tech’s experience that when larger units are treated with the supplement, the amount of oil removed to prevent over filling can exceed the amount added, indicating the film thickness on all internal surfaces decreased. This conclusion is consistent with the observed improvement in heat transfer when Frigi-Tech is used.

CONDITIONERS

Frigi-Tech Refrigeration Oil Supplement also contains conditioners. These conditioners maintain elastomer resiliency and pliability. Elastomer components of mechanical seals, valve packings, case gaskets, hoses, and pressure relief valves are treated to a conditioning additive that keeps them from cracking. Because elastomer in units treated with Frigi-Tech become more resilient and durable, the life of these components is extended.